How Does colorFabb LW-PLA Work?

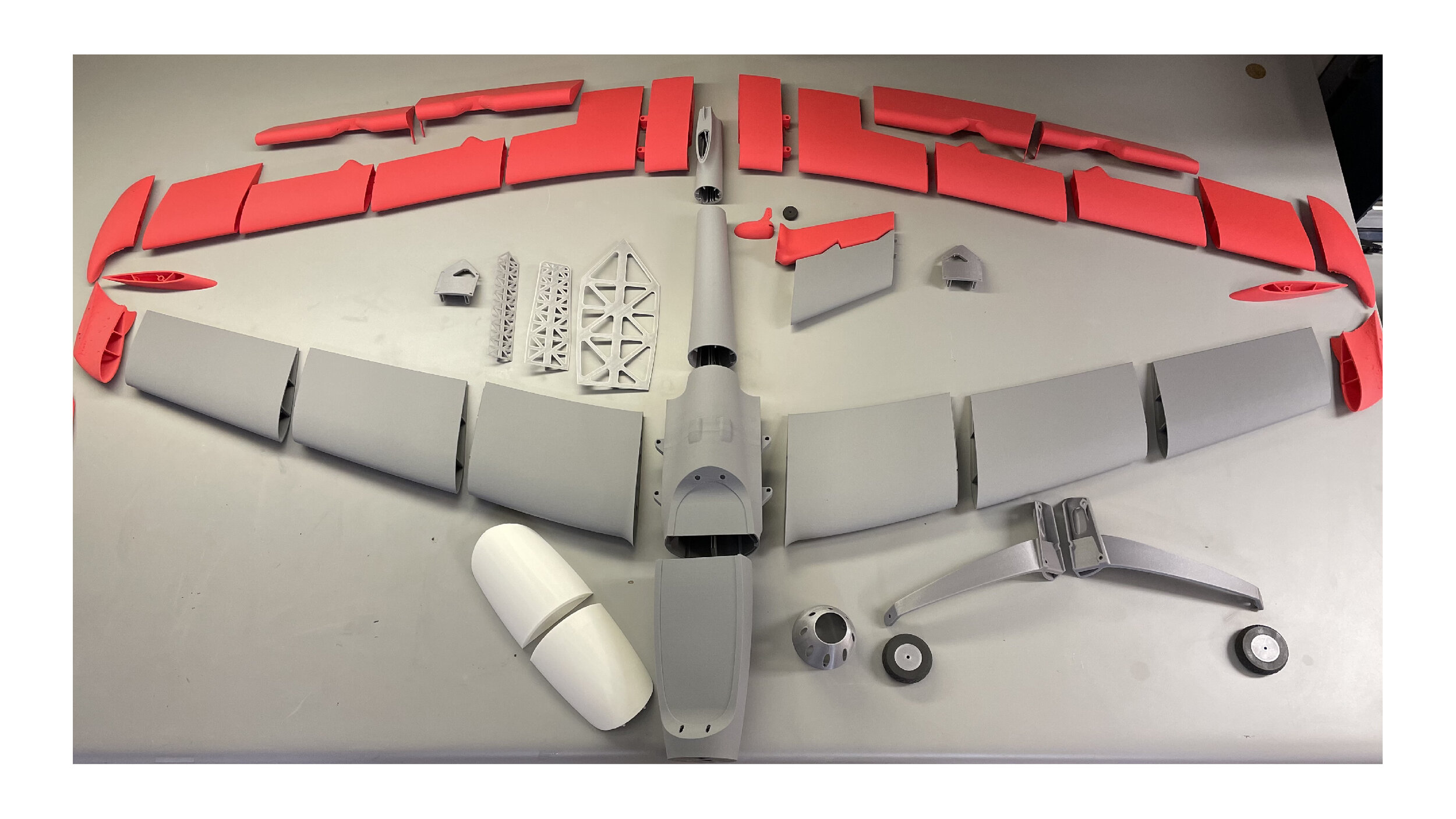

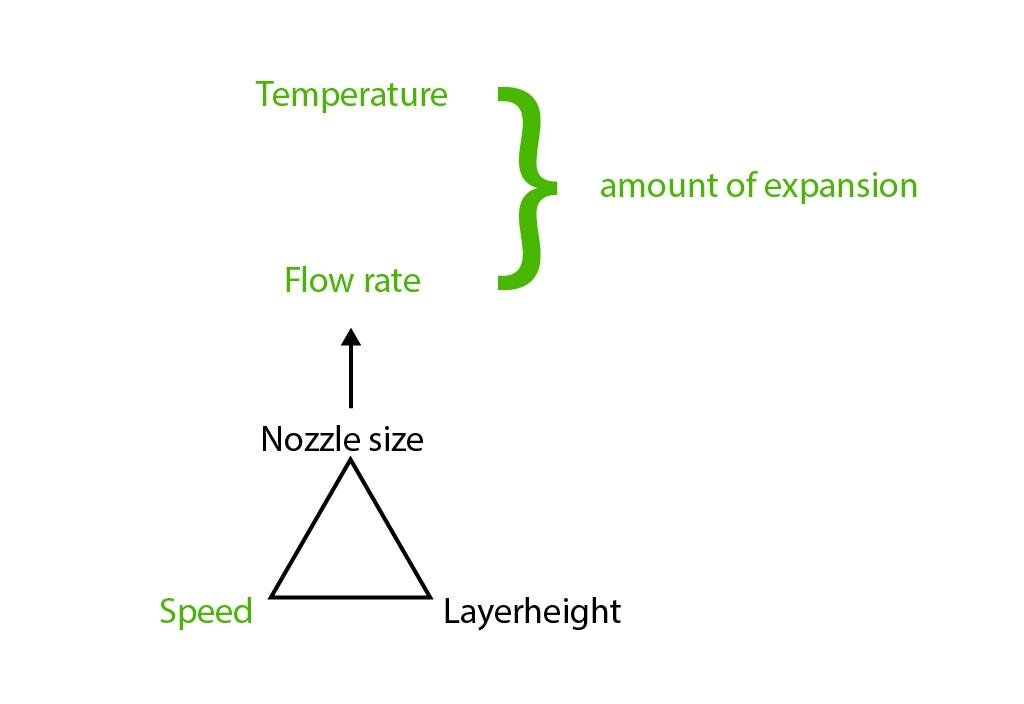

LW-PLA is a PLA material mixed with a foaming additive that activates at elevated temperatures. It will print much like standard PLA at lower temperatures (210C - 220C) but once you print above 230C the foaming technology activates. This foaming effect becomes more aggressive as you continue to elevate the temperature. The key to success when printing with LW-PLA is balancing between print temperature, speed, and flow rate. Once you’re printer and slicer settings are dialed in, you should achieve parts that match the wall thickness of the designed part, but are 35 - 40% the weight of the same part printed in traditional PLA.